Drone Testing

4 min

Assembly Time

26 mph

Max Speed

17 lbs

Drone Weight

3 mi

Flight Range

Our Latest Drone

Zephyrus is an autonomous drone Amador UAVs built for the SUAS competition. It is designed for stability, efficiency, and modularity, it integrates advanced software, electrical, and mechanical systems for peak performance. Featuring PX4 autopilot, GPS waypoints, precise object detection, and an innovative payload drop system, Zephyrus is powered by a 2S2P battery and MN 601-S motors for reliable thrust and endurance. Its carbon fiber and TPU construction ensures durability and portability. Optimized through simulation and testing, Zephyrus delivers high autonomy, minimal operator intervention, and exceptional reliability in dynamic conditions.

Software Systems

Zephyrus’s software enables full autonomy with minimal operator input. It runs PX4 firmware with QGroundControl for mission planning, while a Jetson Nano handles object detection and navigation via Python scripts. The Jetson processes video and manages object tracking and payload targeting independently. Payload drops are triggered by Jetson-detected targets via MAVLink to Pixhawk, then to a servo controller. PX4 handles GPS navigation and PID control. The full stack was validated in Gazebo with PX4 SITL, ensuring reliable behaviors like return-to-home and precise autonomous payload delivery before flight testing.

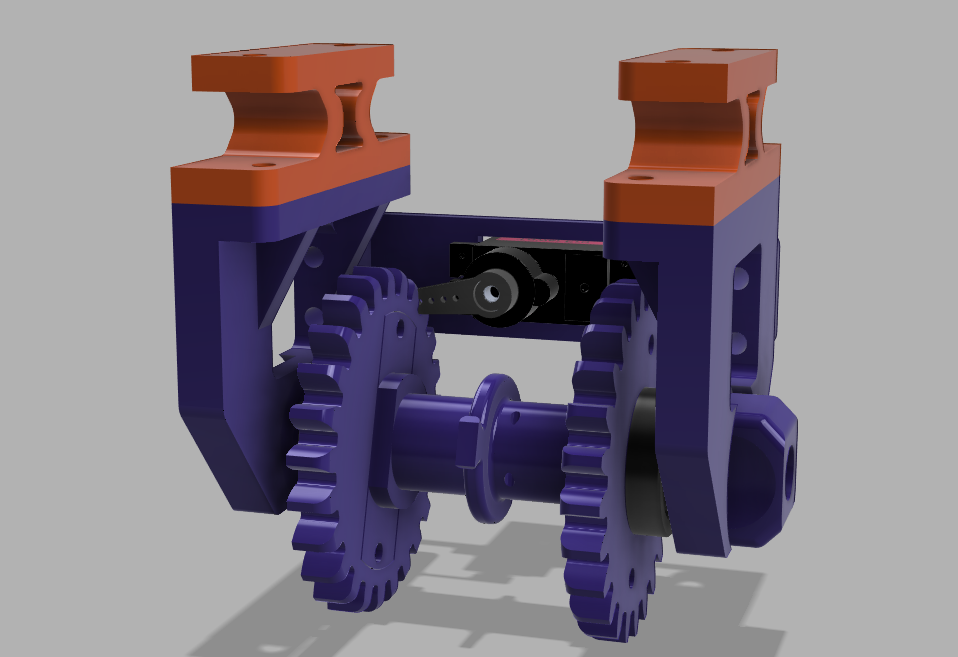

Mechanical Systems

Zephyrus’s mechanical design emphasizes modularity, strength, and rapid deployment while fitting carry-on size limits. Its carbon fiber frame features TPU inserts for shock absorption, with a central hub housing electronics and radial arms for stiffness. Latching clamps and clip-in legs allow fast assembly, and standardized connectors support modular payloads. A servo-driven, spool-based drop system reduces impact, with dampers isolating vibrations. The two-axis brushless gimbal, printed in PA6 CF-20, stabilizes for dynamic object tracking. Design validation included FEA simulations and extensive physical testing for durability and field readiness.

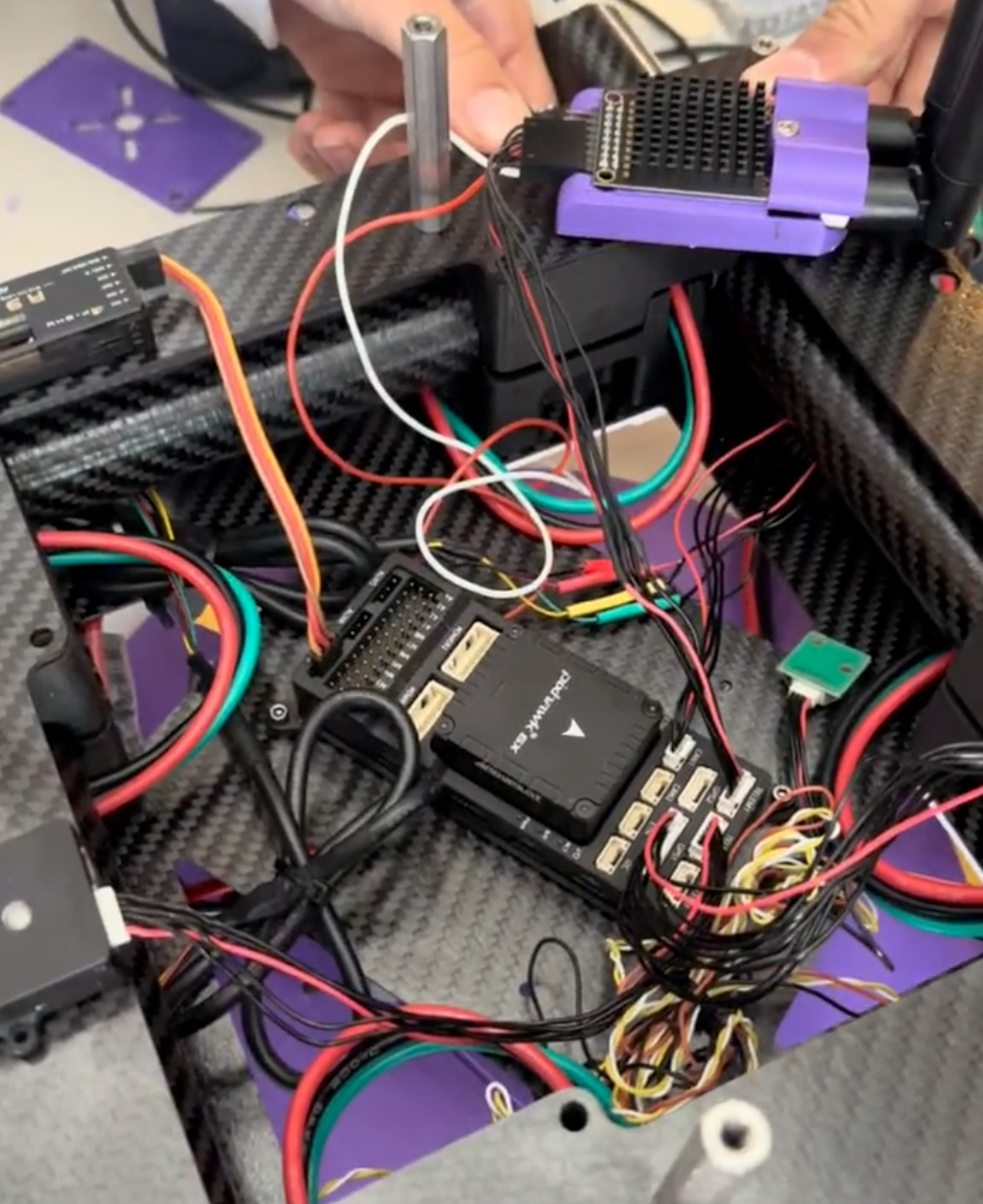

Electrical Systems

Zephyrus features a modular, efficient electrical system with safe power distribution and clean signal routing. It uses a 2S2P 3S LiPo battery (22.2V, 18,000 mAh), centered for balance and field-swappable. A custom voltage board delivers stable 5V/12V to sensitive systems like the Jetson Nano. MN 601-S motors with Zubax Myxa ESCs (CAN Bus) offer precise, low-noise control and telemetry. Ecalc simulations optimized thrust and flight time. A Pixhawk 6x controller, dual GPS, and RFD900 telemetry ensure reliable navigation. Avionics are isolated, vibration-dampened, and easily serviceable.

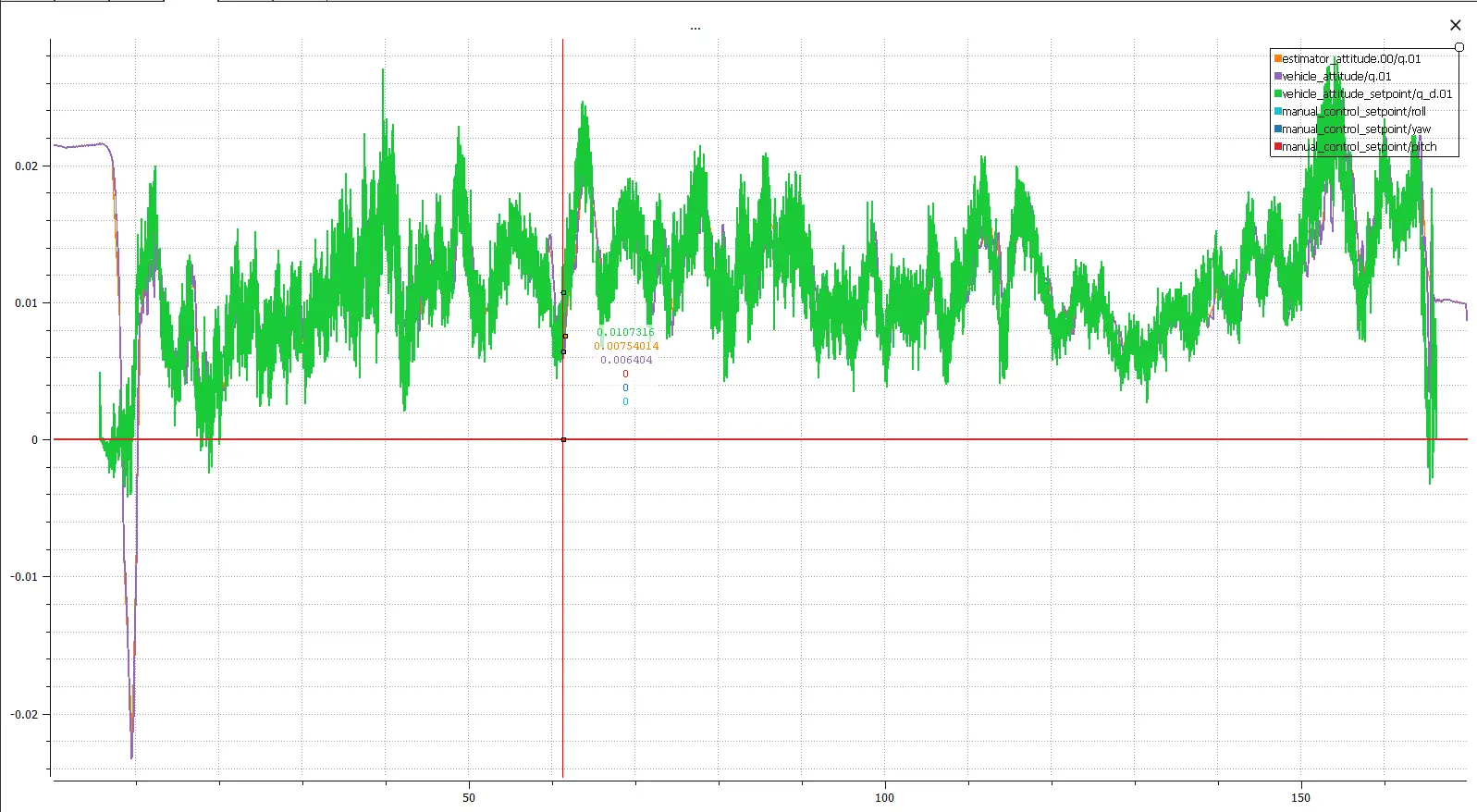

Drone Testing

To prepare Zephyrus for the mission tasks at the SUAS competition, we prioritize flight testing to ensure the drone proves reliable. We test flight stability, autonomous flight plans and individual mechanical parts to assess the overall performance of the drone under conditions similar to the competition. Our thorough testing allows us to find possible issues early on and brainstorm designs to mitigate them in the future for efficiency during the mission.

After every flight, we review the PX4 logs from the drone to check for any abormalities and improve efficency.

Component Specifications

| Subsystem | Component | Specification / Details |

|---|---|---|

| Power System | Battery | 2S2P (6S LiPo), 22.2V, 18,000 mAh |

| Power Distribution | Custom voltage regulator board with 5V and 15V outputs | |

| Motors & Propulsion | Motors | MN 601-S, Brushless DC motors |

| ESCs | Myxa ESCs with CAN Bus communication | |

| ESC Tuning | Ecalc simulations for flight time and thrust efficiency | |

| Flight Control & Communication | Flight Controller | Pixhawk 6x |

| Telemetry | RFD900, long-range radio telemetry | |

| GPS | Dual GPS setup for redundancy | |

| Communication | MAVLink and serial protocols | |

| Onboard Computer | Jetson Orin NX | Runs Python scripts for autonomous control, object detection, and navigation |

| Payload Mechanism | Servo | MG90s micro servo for payload release |

| Payload Control | Spool-based system with directional winding; TPU dampers for vibration isolation | |

| Gimbal System | Type & Material | 2-axis brushless gimbal; PA6 CF-20 filament for strength and thermal stability |

| Stabilization | Gyro-based real-time alignment with object detection algorithms | |

| Structural Integrity | Frame Material | Carbon fiber frame with TPU shock absorption |

| Design | Modular, vibration-isolated avionics platform for easy replacement | |

| Testing | FEA simulations (Onshape) for load and torque validation |

AmadorUAVs Group

© 2018 - 2025 | EIN 99-4292368